Ecommerce Inventory Management

Did you know that over $1.77 trillion worth of merchandise was lost to inventory distortion globally in 2022? In the competitive world of ecommerce, where speed and customer satisfaction reign supreme, effective inventory management is no longer a luxury, but a necessity for survival.

Simply put, ecommerce inventory management is the art and science of tracking, controlling, and optimizing your stock levels to meet customer demand without overspending or running out of crucial items. But in reality, it often feels more like a high-stakes balancing act between forecasting demand, managing storage, and fulfilling orders, all while navigating unexpected disruptions.

This article will delve into the core principles of successful ecommerce inventory management, equipping you with the knowledge to minimize losses, maximize profits, and ultimately, deliver a seamless shopping experience that keeps your customers coming back for more.

Get ready to discover proven strategies and best practices to transform your inventory from a potential liability into a powerful asset.

E-Commerce Inventory Management: A Guide for Growing Businesses

Understanding E-Commerce Inventory Management

E-commerce inventory management is simply tracking stock. It’s knowing what you have, where it is, and how much is available.

Good stock control is key to order fulfillment. Efficient procedures help satisfy customers and keep them coming back for more.

Poor inventory management, meanwhile, can lead to issues. Think lost sales from stockouts or high storage costs from overstocking.

Therefore, grasping how to effectively manage your product levels ensures your e-commerce business remains profitable and competitive.

Ultimately, strategic inventory management reduces operational costs, boosts profitability, and allows you to focus on expansion. You’re not just selling; you’re building a sustainable brand.

Why Inventory Management Matters for Online Stores

Consider the customer experience. Nobody likes ordering something online and being told it’s suddenly unavailable. That’s a quick way to lose a buyer.

Precise management allows you to meet customer expectations. Ship orders on time and avoid overselling, which builds trust and loyalty.

Also, think about your bottom line. Excess stock ties up cash. Efficient management ensures your capital is used wisely, not sitting on shelves.

Effective stock control also helps you adapt to trends. You can anticipate demand and adjust your stock accordingly, boosting sales.

In a nutshell, inventory management affects your brand image. From handling orders to building a base, a smooth process sets you apart.

Common Inventory Management Challenges in E-Commerce

One of the biggest struggles is demand forecasting. Predicting what will sell and when can be difficult, especially with trending products.

Another challenge is dealing with multiple sales channels. Managing stocks across various platforms can be complex without a central system.

Returns and exchanges are another hurdle. Handling returned items and restocking them appropriately requires a detailed process.

Also, manual tracking is prone to errors. Reliance on spreadsheets can lead to data discrepancies and inaccurate stock levels.

Finally, scaling inventory management is tough. As your business expands, you will need to implement more robust systems to cope with increased demand.

Effective Inventory Management Techniques

First-In, First-Out (FIFO) ensures older stock is sold first. This is especially important for products with expiration dates or seasonality.

Just-in-Time (JIT) minimizes stock on hand. You receive inventory precisely when you need it, reducing storage costs and waste.

ABC analysis categorizes inventory based on value. ‘A’ items are high-value, ‘B’ are medium, and ‘C’ are low, guiding focused management.

Cycle counting involves regularly counting a small amount of inventory. This helps to identify and correct discrepancies quickly.

Safety stock maintains extra product levels. This strategy buffers against unexpected demand spikes or supply chain disruptions.

Tools and Software for E-Commerce Inventory Management

Inventory management software automates tracking. Features include stock level alerts, order fulfillment, and reporting functions.

Barcode scanners improve accuracy and efficiency. Scanning items during receiving and shipping minimizes errors and saves time.

Cloud-based systems offer real-time visibility. You can access your inventory data from anywhere, enhancing control and collaboration.

Integration with accounting software streamlines finances. It ensures that inventory data is synced with your financial records.

Consider features like order management and shipping. This capability unifies your fulfillment processes for better workflow.

Implementing a Successful Inventory Management System

Start by assessing your current processes. Identify pain points and areas for improvement. Take an honest look to move forward.

Set clear goals for your inventory management. Define metrics to measure success, like reducing stockouts or improving order accuracy.

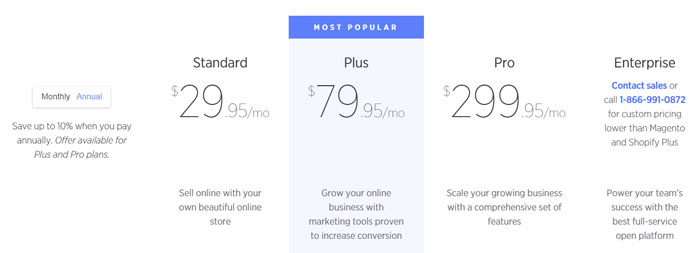

Choose the right tools based on your needs. Consider the size of your business, the volume of sales, and your budget constraints.

Train your staff on the new system. Provide thorough training to ensure everyone understands how to use the tools effectively.

Regularly monitor and adjust your system. Continuously evaluate the effectiveness of your processes and make changes as needed.

Inventory Forecasting: Predicting Future Demand

Analyzing past sales data provides insights. Look at trends, seasonality, and promotional impacts to forecast demand accurately.

Consider external factors like market trends. Stay informed about industry changes and consumer behavior to refine your predictions.

Utilize forecasting tools and software. These can automate the process, providing more precise and reliable demand predictions.

Collaborate with your sales and marketing teams. Their insights on upcoming promotions and product launches can improve forecasts.

Regularly review and update your forecasts. Fine-tune your predictions based on actual sales data and changing market conditions.

Optimizing Your Warehouse Layout for Efficiency

Efficient warehouse layouts can save time and effort. Organize your space to streamline the flow of goods from receiving to shipping.

Designate specific zones for different functions. Create separate areas for receiving, storage, picking, packing, and shipping.

Implement a logical storage system. Use shelving, racking, and other storage solutions to maximize space and accessibility.

Optimize picking paths to minimize travel time. Arrange items based on popularity to reduce the distance pickers need to travel.

Ensure adequate lighting and clear signage. Make it easy for staff to navigate the warehouse and locate items quickly.